Computing is a must in manufacture and industry such as the office sector. In addition to many automated manufacturing processes that must be controlled by computers, many applications such as stock control and shipping are now far more efficiently achieved with the help of the processor. However, industrial and manufacturing needs are far different from what is needed from the office PC.

Most office hardware runs in optimal conditions: the air-conditioned suite is well, free from dust, water and without the risk of being borne or tapped by heavy machinery. Unfortunately the demands of manufacturing and industries are very different.

Many industrial environments are dusty, dirty and dirty. Often temperatures can exceed recommendations for most computer equipment (especially if the industrial environment contains furnaces or freezers where operating conditions can be described as extremes) and the picked truck fork and pallet trucks are grouped in and out of the lane.

Industrial PC requirements are very different from the need for office computers. Industrial computer needs will also vary dramatically depending on the industry itself. Computers used in food manufacturing may have to be waterproof and sealed intrinsically to prevent explosions in the atmosphere that potentially explode and dusty while also made of stainless steel or materials that are easy to clean. But the computer in the heavy industry may also have to protect from dust and dirt but can withstand excessive temperatures, beats and vibrations.

High demands for computing in the industry. Industrial machinery must overcome many hostile elements while also providing reliable computing. Traditional industrial computers have been specific and bespoke. This industrial computer tends to run hardware and old software versions. While this has the advantage of making a stable and reliable engine, out-date technology can mean the process controlled by the machine is not done as efficiently. These machines are also very expensive and must be replaced regularly as hardware and software will eventually become obsolete.

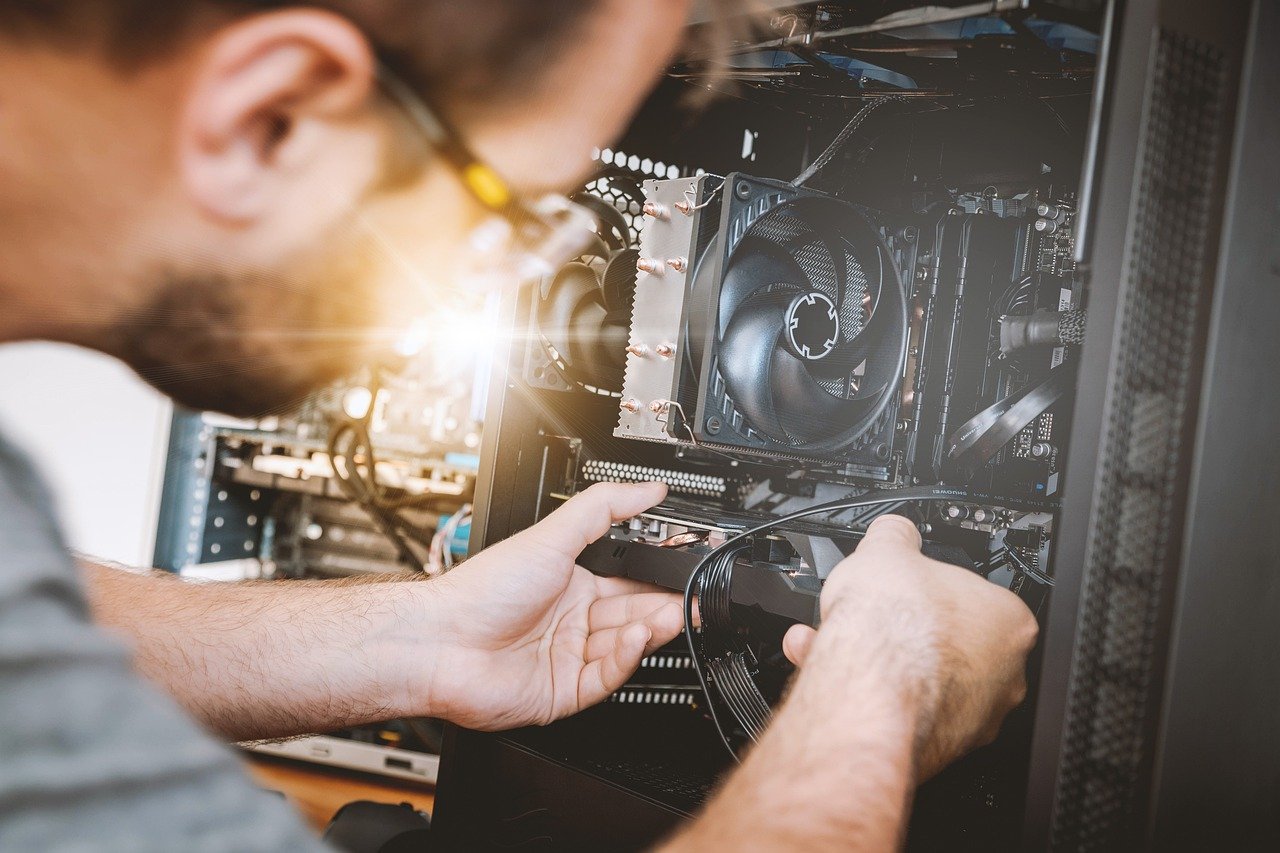

A better solution for varying and extreme computing demands in the industry is to use a conventional PC but located at an industrial PC cage. It has all the benefits of traditional industrial computers such as being able to withstand dirt, dirt, dust, gas, beats, bangs, heat and cold while having normal PC flexibility. Allows you to choose, repair, replace or improve your machine rather than waiting for an engineer. This attachment can also be reused and will last longer than an industrial PC which will eventually fail (like all PCs). However, the cage can be used again long after the original computer will expire.

With the demands of industrial computing so that variables and extremes, Industrial PC attachments offer the flexibility that even conventional industrial computers can cause temporary match also offer the same protection and reliability for a fraction of the cost. PC enclosures are ideal for the most hostile industrial environment and while specialist PCs will always be needed for certain tasks the majority of use for industrial computers can be achieved by using a conventional PC located at home.